The University of Toronto’s new Academic Wood Tower presents a unique opportunity to incorporate sustainable heating by adding a heat recovery chiller to its basement mechanical room. This chiller will play a critical role in the university’s decarbonization efforts by upgrading waste heat from the building’s chilled water system. However, the chiller’s substantial size posed a challenge: it was simply too large to be rigged through the basement doors and existing slab openings.

Solutions in Action

HTS Service and Logistics were instrumental in tackling this complex project:

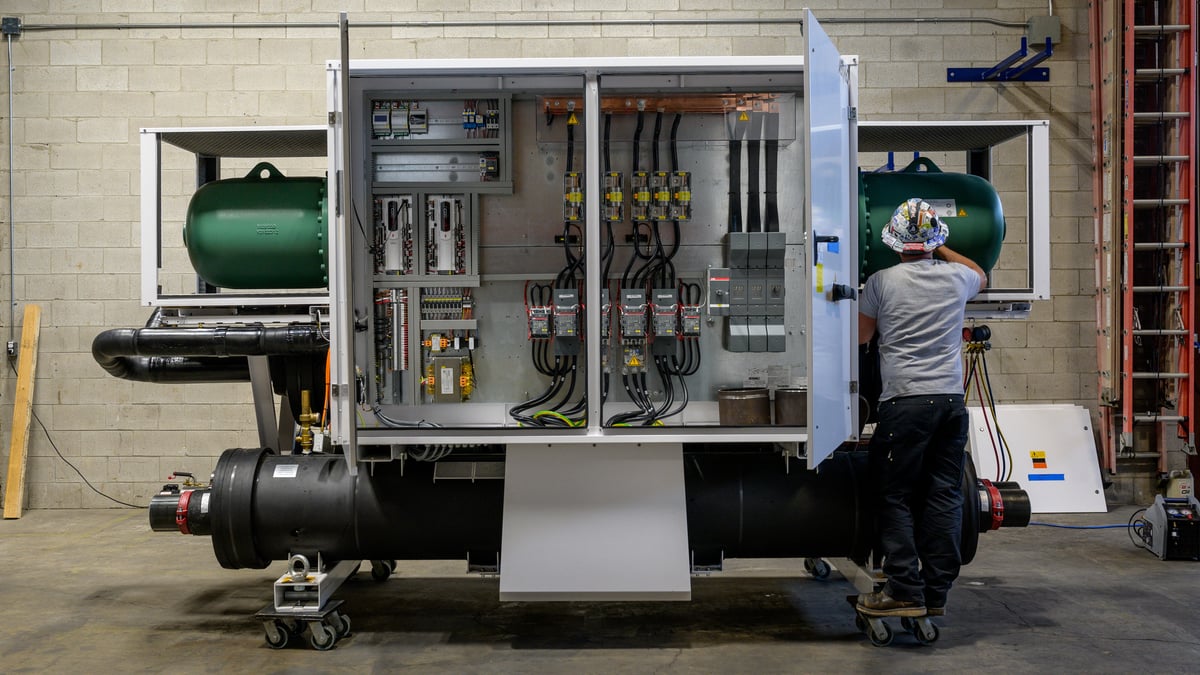

- Logistics: Our logistics team managed the arrival of the 18,000 lb chiller at our Concord warehouse, ensuring secure handling and storage.

- Expert Disassembly and Labeling: The HTS Service team disassembled the chiller with detailed labelling and preparation to meet on-site space limitations.

- Seamless Transportation: The disassembled chiller was carefully loaded onto a flatbed truck and transported to the university, where it was ready for crane offloading.

- Collaboration for Installation: Partnering with the mechanical contractor, HTS rigged each component into the tight mechanical room space and reassembled it in place.

Despite the restricted entry points and confined space, the heat recovery chiller was successfully installed in the basement of the Academic Wood Tower, advancing U of T’s sustainability goals and enhancing the building's heating efficiency.