Discover the essential factors and best practices for designing high-performance AHUs that enhance indoor air quality, energy efficiency, and occupant comfort in various construction environments.

Managing Snow Entrainment in Cold Climates

One of the critical challenges faced in cold climates is snow entrainment, which occurs when fluffy snow is carried into the airstream. At airflow velocities as low as 50 feet per minute (fpm), snow can be drawn into the system, potentially leading to operational inefficiencies, water accumulation, and even airflow stoppages.

Since completely eliminating snow entrainment is impossible, the focus should be on effective management strategies:

- Low-Velocity Outdoor Air (OA) Inlets: Reducing the velocity of incoming air can minimize the amount of snow entering the system.

- Drainage Systems: Implementing full drain pans or floor drains ensures proper evacuation of melted snow and water.

- Pre-Heat Coils and Infrared Systems: A glycol pre-heat coil can act as a snow-melting system, while infrared heating elements can assist in evaporating accumulated snow before it enters the unit.

Preventing Moisture Carry-Over for Improved Performance

Moisture carry-over occurs when condensation from components such as cooling coils, heat recovery devices, and humidifiers is picked up by the airstream and transported downstream. If not managed properly, this can lead to corrosion, flooded plenums, water damage to building structures, and even compromised air quality.

To mitigate these risks, consider the following:

- Component Selection: Using properly sized cooling coils (below 500 fpm), heat recovery devices with outside air (OA) bypass features, and well-positioned humidifiers prevents excessive moisture build-up.

- Moisture Management Devices: Extended and sloped drain pans, moisture eliminators, and intermediate drain pans can capture and direct water to appropriate drainage points.

- Optimal Unit Layout: Ensuring good air mixing, correct humidifier placement, and proper face velocities for cooling coils reduces moisture-related issues.

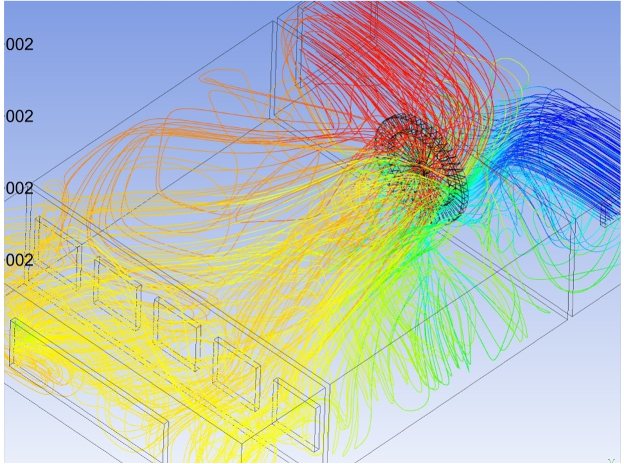

Minimizing Air Stratification

Stratification occurs when multiple air streams—such as outdoor air (OA) and return air (RA)—do not mix effectively, leading to temperature inconsistencies and reduced coil efficiency. Poor air mixing can result in sensor errors, inefficient heating or cooling, and discomfort in conditioned spaces.

Best practices to avoid stratification include:

- Proper Mixing Section Design: Positioning OA and RA inlets close to each other, using parallel blade dampers, and keeping air velocities between 1,200–1,500 fpm enhances mixing efficiency.

- Mixing Baffles and Blenders: Adding baffles or blenders forces air streams to mix more thoroughly, reducing temperature variations and improving overall performance.

- Minimum OA Dampers: Including a dedicated minimum OA damper ensures fresh air is introduced efficiently without disrupting system balance.

Addressing AHU Sound Levels

Noise control is an essential aspect of AHU design, particularly in applications such as hospitals, offices, and residential buildings where excessive sound levels can cause discomfort. Since fans are the primary noise source, selecting the right fan type and implementing sound attenuation measures is key.

Sound mitigation strategies include:

- Fan Selection: Determining how critical sound levels are and selecting AMCA-certified fans optimized for sound can significantly reduce noise levels.

- Unit Construction: Using casing materials with appropriate wall thickness, perforated liners, and insulation (such as mineral wool or fiberglass) can dampen noise.

- Silencers and Baffles: Installing silencers on both the supply air (SA) and return air (RA) sides, as well as using internal sound baffles, can further minimize sound transmission.

Ensuring Proper Clearance for Maintenance and Testing

Proper clearances around an AHU are essential for maintenance accessibility, component removal, and electrical servicing. Insufficient space can lead to operational inefficiencies and increased maintenance costs.

Key clearance considerations include:

- Access Doors and Component Pull Spaces: Allowing adequate room for opening access doors and removing components such as coils and filters ensures easier servicing.

- Electrical Maintenance Clearances: A minimum clearance of 1 meter in depth and 2.2 meters in height is typically required in Canada for safe electrical maintenance.

- Leak and Deflection Testing: High-quality AHUs are tested for leakage rates (<1% at 1.5x total static pressure), structural integrity, vibration compliance, and sound attenuation to ensure optimal performance and energy efficiency.

Conclusion

Optimizing AHU design is a multi-faceted process that requires careful consideration of environmental factors, system layout, component selection, and maintenance accessibility. By implementing best practices for managing snow entrainment, moisture carry-over, stratification, sound attenuation, and clearances, HVAC professionals can enhance the efficiency, reliability, and longevity of AHU systems.

Investing in high-quality AHU design not only improves energy efficiency and occupant comfort but also reduces long-term operational and maintenance costs. By leveraging these insights, HVAC engineers and facility managers can make informed decisions that lead to better-performing air handling systems.