Unsurprisingly, the greatest potential for ventilation air energy recovery in Ontario comes during the coldest winter weather. This is when the largest temperature differential exists between the indoor air and outdoor air conditions. However, it is under these low ambient conditions that ERVs will be most likely to encounter issues with frost formation on the surface of their integral recovery device.

Frost is generated on an energy recovery device when the exhaust air leaving temperature is below freezing (0°C) and moisture in the exhaust air stream starts to condense (i.e., 100% RH (Relative Humidity)). The impact of frost formation on ERV performance is further magnified in higher efficiency ERVs and/or when the incoming exhaust air humidity is high.

With this information, we can identify a few common control options to identify whether a frost condition exists.

|

Option |

Description |

Considerations |

|

OA (Outside Air) Temp |

Anytime the OA entering temperature is below a preset temperature set point the defrost/frost prevention sequence is initiated. |

|

|

EA (Exhaust Air) Temp |

Anytime the EA leaving temperature is below a preset temperature set point the defrost/frost prevention sequence is initiated. |

|

|

EA Temp & RH |

When the EA LAT is below 0oC and the EA RH is above 95%, the frost prevention sequence is initiated. |

|

|

EA Pressure Drop |

An increase in APD (air pressure differential) across an energy recovery device will indicate a build-up of frost and the defrost/frost prevention sequence is initiated. |

|

Once a frosting scenario has been identified, we need an ERV frost management strategy which will either prevent frost from forming in the first place or one which will melt any ice which has formed. A summary of the various ERV frost prevention/defrost strategies are included below:

|

Strategy |

Description |

Considerations |

|

EF Only |

Defrost: Only the supply fan stops, allowing the exhaust air to melt any built-up ice. |

|

|

Recirculate |

Defrost: A recirculation damper opens and only the supply fan remains in operation. Any built-up ice is melted by the recirculating air. |

|

|

Stop-Jog (Wheel Only) |

Defrost: The energy recovery wheel is stopped for a while and then jogged, allowing the exhaust air to melt any built-up ice. |

|

|

Modulating Wheel (Wheel Only) |

Prevention: Energy recovery wheel speed is reduced to avoid frost accumulation via reduced recovery effectiveness. |

|

|

OA Bypass |

Prevention: OA bypass damper is modulated to reduce air flow through the OA side of the energy recovery device avoiding frost accumulation via reduced recovery effectiveness. |

|

|

Preheat |

Prevention: Preheat OA as required to eliminate a frost scenario from occurring. See Figure below. |

|

If we are using an OA Bypass or Modulating Wheel approach, we are effectively restricting the energy recovery device to prevent the exhaust air from reaching the Saturated Air condition on the chart below. You can also see that by injecting a small amount of heat into the incoming fresh air, we can eliminate the Saturated Air condition for the ERV altogether.

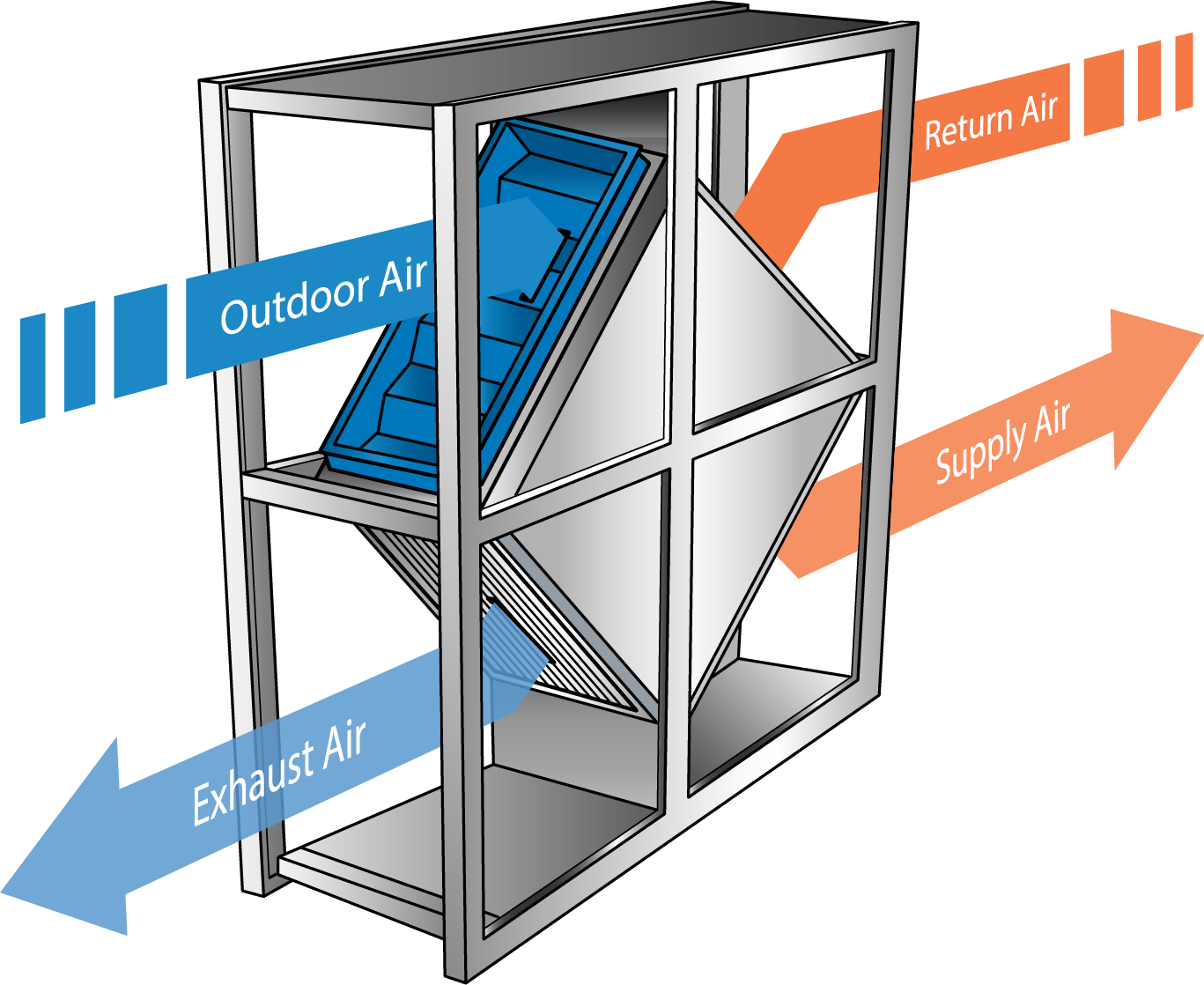

An alternative energy recovery device that does not require any defrost strategy whatsoever is a DualCore® ERV (https://www.tempeff.com/dual-core-difference/).

The alternating nature of its operation has the effect of thawing any frost that forms when the airstream switches directions, meanwhile generating a small amount (typically 2-3%) of cross contamination. This solution can consistently provide ~90% sensible efficiency throughout the entire heating season.

|

Recovery Device |

Heat-Pipe |

Crossflow Plate |

Wheel |

Counter-Flow Plate |

Dual Core |

|

Layout |

|

|

|

|

|

|

Recovery Type |

TEMP |

TEMP / TEMP & RH |

TEMP / TEMP & RH |

TEMP / TEMP & RH |

TEMP / TEMP & RH |

|

Effectiveness |

45-60 % (sensible) |

50-65 % (Total) |

65-80 % (Total) |

65-80 % (Total) |

70-90 % (Total) |

|

Frost Prevention Strategies |

|

|

|

|

|

|

Defrost Strategies |

|

|

|

|

|

Dealing with frost can be a challenge, so it is important to visually verify that the frost mitigation strategy is working during the first season of operation and tweak the control strategy as needed. Consider exploring DualCore® ERVs for any application where cold weather is a concern, to protect downstream equipment and when there is a desire to reduce energy costs.